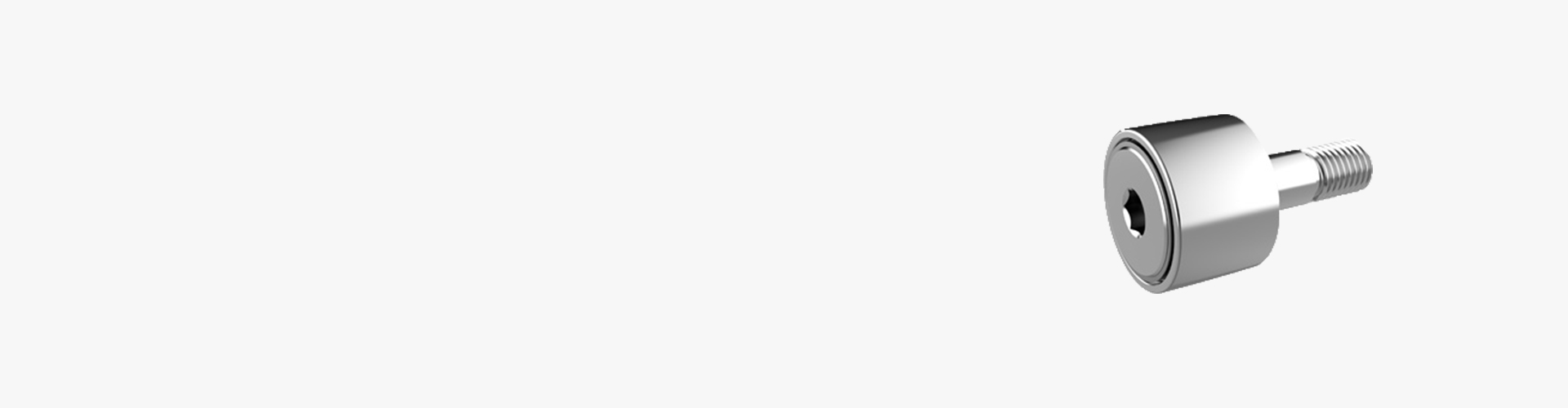

How to Choose the Ideal Cam Follower?

The following factors can be considered.

the operating environment, such as the operational requirements of your equipment

speed of operation and maintenance, the stability of the equipment is one of the main objectives to be pursued.

ease of installation.

Choosing the right cam followers will help to ensure that your equipment runs consistently, accurately and efficiently, thus avoiding downtime, saving labour requirements and reducing costs.

Cam Followers Types

Various Structures of CAM FOLLOWERS (various designs and variants)

Roller element: needle roller or cylindrical roller

Cage: with or without cage

Eccentric sleeve: with or without eccentric sleeve

With the combination of the above different structures, THB can provide you with the following models:

KR/KRV/KRE/NUKR/PWKR/NUKRE/PWKRE

Size Range of THB Cam Followers

The size range of KRV is: inner diameter 6-30mm, outer diameter 16-90mm, width 12.2-37mm

The size range of NUKR/PWKR is: inner diameter 16-30mm, outer diameter 35-90mm, width 19.6-37mm

Technical Information of THB Cam Followers

Lubrication

THB cam follower has been filled with lithium-based grease and can be re-lubricated through the special oil hole for the bolt shaft. Equivalent grease can be used for re-lubrication.

THB can also provide targeted lubrication programs, if necessary, please contact the THB technical department

Working temperature

Limited by the grease and sealing material, the KR, KRV, and KRE series are suitable for an operating temperature range of -30 °C to +100 °C

Sealing

Cam followers have seals on both sides. For the sealing form, please refer to the corresponding parameter table.

Seal model description:

| 2RS | Lip seal on both sides of the yoke type track roller. |

| 2Z | Metal shield on both sides of the track roller bearing. |

| 2RSR | Radical contact lip seal on both sides of the yoke type track roller bearing. |

| 2ZL | Sealing shield with lamellar rings on both sides of the track roller bearing. |

High radial load, can withstand combined loads, long life, easy to install

High radial load: the thicker wall outer ring not only withstands high radial loads, but also reduces deformation and bending stresses when working as a roller.

Axial loads can be sustained: cylindrical roller bolt shaft rollers with baffled edges can withstand axial loads that may result from off-loading or inclined operation.

Long service life: The convex design of the outer ring surface can be greatly improved where the outer ring may be inclined in relation to the working track surface or where edge stresses need to be minimised.

Easy to install: The design of the bolt shaft construction allows for quick and easy installation of the bolt type roller onto the corresponding machine component with hexagonal nuts.

English

English français

français Deutsch

Deutsch italiano

italiano