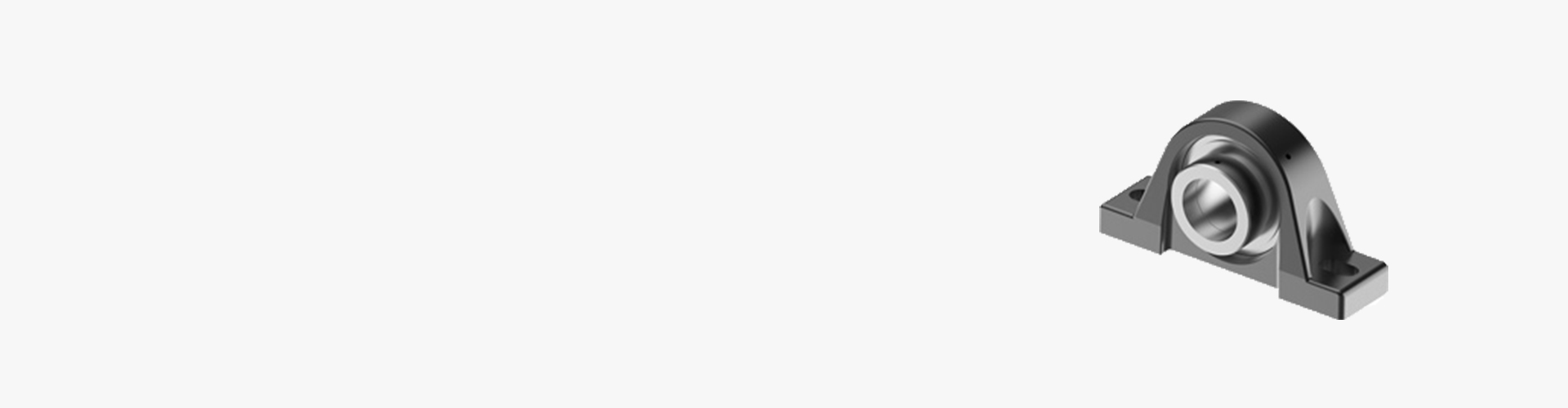

How to Choose Pillow Block Bearing?

-

Shaft diameter or bore of pillow block bearing

Calculate the loads according to the customer's selection, and determine the shaft diameter or the bore of pillow block bearing with sufficient rigidity and deflection.

-

Shaft height position

Determine the height of the shaft center from the mounting base of pillow block bearing according to the structure size of the mechanism.

-

The shaft maximum speed

According to the working speed of the shaft, THB, as a professional pillow block bearing supplier, determines whether the limit speed of the bearing with a seat can meet the application requirements.

-

The maximum load of the pillow block bearing

According to the load of the entire shafting system, the load of pillow block bearing would be verified, including the fatigue life of the bearing and the strength of the pillow blocks.

-

Misalignment performance

According to the misalignment information required in the shafting design, select the appropriate type and configuration of pillow block bearing.

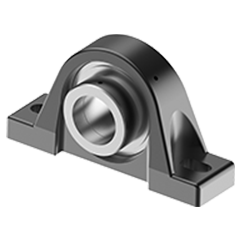

The Installation of Pillow Block Bearing

Mounting steps for pillow block bearing:

-

Step 1

Check whether the position tolerance of the connecting hole at the mounting position of pillow block bearing and the flatness of the fixed base surface of pillow block bearing meet the requirements.

-

Step 2

Clean pillow block bearing and pillow block bearing to be installed on the base position and the surface of the shaft with a cleaning agent to keep the surface free of impurities and dust, and coat the surface with a layer of anti-rust oil.

-

Step 3

Install the shaft into the bore of inserted bearing, during the installation process, only use tools such as a rubber hammer or nylon rod to strike the end face of the insert bearing's inner race to move, and do not strike other positions of other bearing housings.

-

Step 4

After pillow block bearing is installed in the proper position of the shaft, fix pillow block bearing on the base, and tighten the bolts according to the specified torque requirements.

-

Step 5

After installing the pillow block bearings at both ends, the shaft should be able to move axially between the bearing holes with a certain amount of force, which can ensure good alignment of pillow block bearing at both ends. Otherwise, it is necessary to reposition and adjust pillow block bearing.

-

Step 6

Use appropriate torque to alternately tighten the eccentric sleeves on the inner ring of the bearing at both ends to ensure that the bearing is firmly fastened to the shaft.

English

English français

français Deutsch

Deutsch italiano

italiano