- Why Choose THB

-

Bearing Products and Solutions

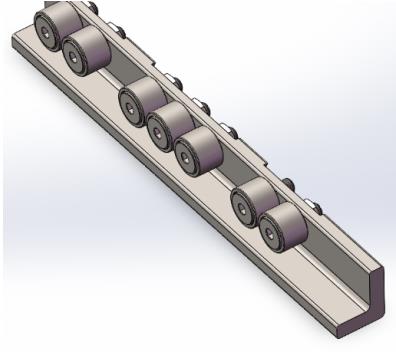

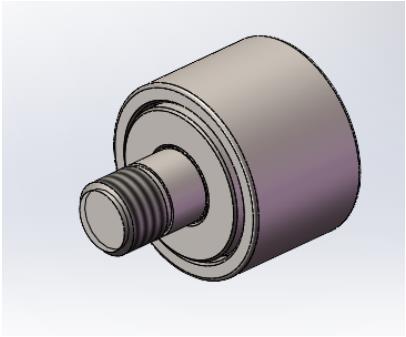

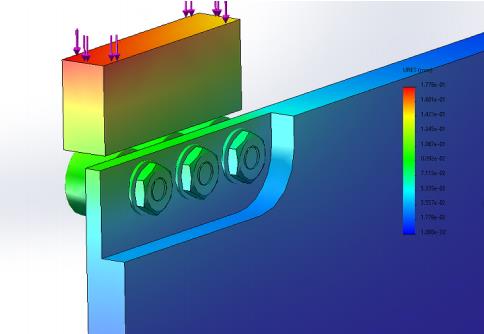

THB BearingsTrack Roller Deep Groove Ball Bearing Self-aligning Ball Bearing Angular Contact Ball Bearing Thrust Ball Bearing Needle Roller Bearing Cylindrical Roller Bearing Spherical Roller Bearing Tapered Roller Bearing Thrust Roller Bearing Crossed Roller Bearing Slewing Ring Pillow Block Bearing Plain Bearing

- Bearing Technical and Support

- Contact Us

English

English français

français Deutsch

Deutsch italiano

italiano