THB deeply understands that customers are not only looking for products, but also for "solutions that fit their equipment". Therefore, understanding the critical requirements of the equipment is the first step for THB to provide services and products to customers.

In this case, the critical information about the customer's equipment includes:

Firstly, the customer needs to be able to perform high-precision operations to ensure product quality and stability.

Secondly, the customer also wants the equipment to reduce maintenance frequency and avoid abnormal shutdowns, thereby ensuring that the production line is not disrupted.

Finally, the customer needs the equipment to have the ability to operate for a long time to improve production efficiency and reduce costs.

Based on the above equipment requirements, THB provides the following solution for the customer:

THB SOLUTION

FINAL MODEL SELECTION

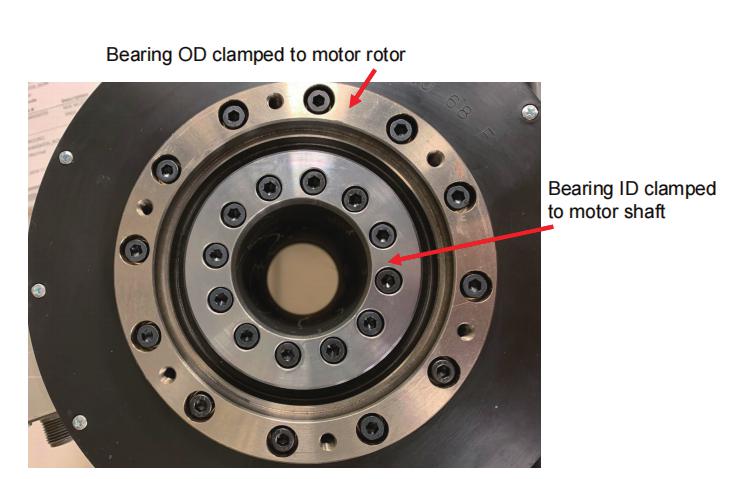

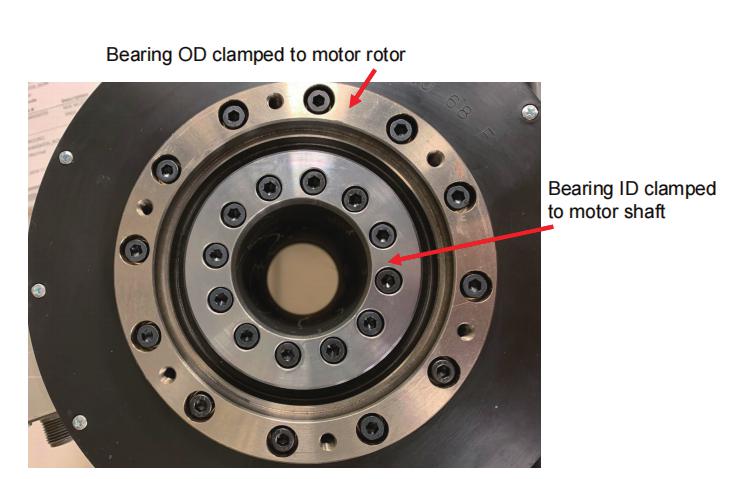

After considering the characteristics of our customers' equipment, THB carefully chooses each reinforced precision crossed roller bearing.

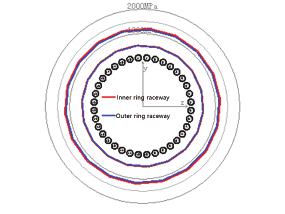

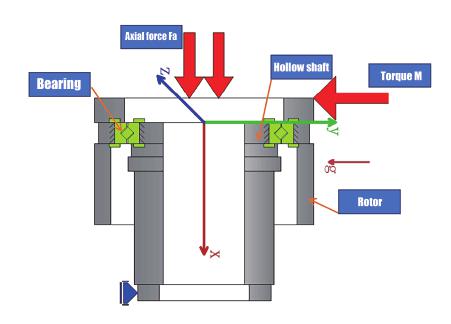

Fig. 1: Bearing assembly schematic

PRODUCT DESIGN OPTIMIZATION

01 Optimize the internal structure design by modifying the isolation block structure to enhance oil storage capacity. Change the bearing seal contact structure to reduce grease loss due to frictional heating.

02 Optimize internal tolerances to reduce unwanted temperature spikes

03 Improve the bearing's overall precision to ensure adequate overall positioning and rotational precision.

Fig. 2: Post-optimization bearing structure schematic

SOLUTION VERIFICATION

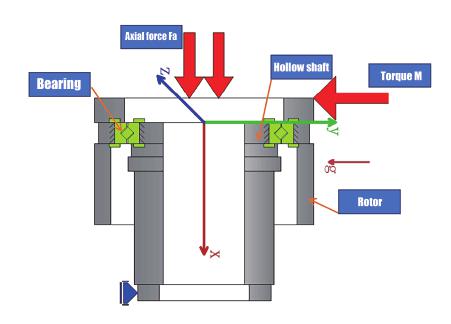

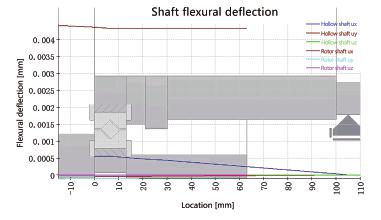

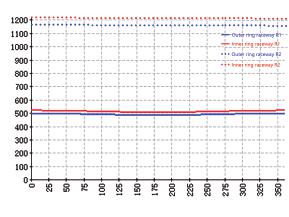

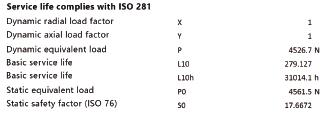

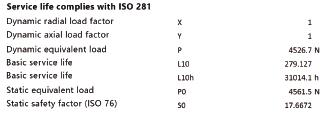

Verification with special software: A results-oriented analysis on bearing service life and static safety is carried out by using bearing-specific service life analysis software, proving that both service life and static safety factor meet customer requirements.

Fig. 3: Bearing assembly and stress schematic

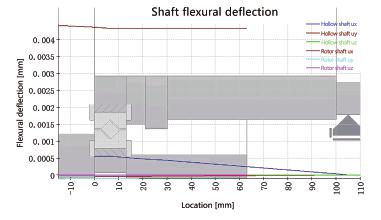

Fig. 4: Shaft flexural deflection curve

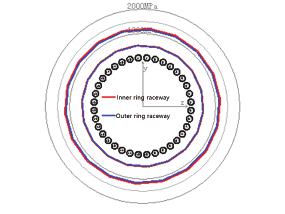

Fig. 5: Contact stress on inner and outer ring raceway

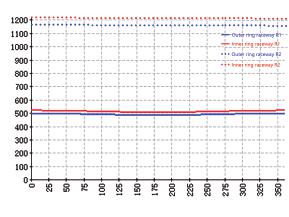

Fig. 6: Roller contact stress

Fig. 7: Calculation results of service life

EXPECTED BENEFITS FROM THIS SOLUTION

The product, after being delivered and put into use, is subject to regular one-month, three-month, six-month and one-year testing, verifying that it operates steadily with a high degree of accuracy, yielding a service life that far exceeds customer expectations.

English

English français

français Deutsch

Deutsch italiano

italiano